Prototype PCB Assembly Service Multilayer Quick Turn Circuit Board

Manufacturing

Technical Requirement for PCB Assembly service

1) Professional Surface-mounting and Through-hole soldering

Technology

2) Various sizes like 1206, 0805, 0603 components SMT technology

3) ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

4) PCB assembly service With CE, FCC, Rohs Approval

5) Nitrogen gas reflow soldering technology for SMT.

6) High Standard SMT&Solder Assembly Line

7) High density interconnected board placement technology capacity.

.

Often encountered materials in PCB assembly service

-

FR-2,

phenolic paper or phenolic cotton paper, paper impregnated with a

phenol formaldehyde resin. Common in consumer electronics with single-sided boards.

Electrical properties inferior to FR-4. Poor arc resistance.

Generally rated to 105 °C.

-

FR-4, a woven

fiberglass cloth impregnated with an

epoxy resin. Low water absorption (up to about 0.15%), good insulation

properties, good arc resistance. Very common. Several grades with

somewhat different properties are available. Typically rated to 130

°C.

-

Aluminum, or metal core board or

insulated metal substrate (IMS), clad with thermally conductive thin dielectric - used for

parts requiring significant cooling - power switches, LEDs.

Consists of usually single, sometimes double layer thin circuit

board based on e.g. FR-4, laminated on aluminum sheet metal,

commonly 0.8, 1, 1.5, 2 or 3 mm thick. The thicker laminates

sometimes also come with thicker copper metalization.

-

Flexible substrates - can be a standalone copper-clad foil or can be laminated to a

thin stiffener, e.g. 50-130 µm

-

Kapton or

UPILEX, a

polyimide foil. Used for

flexible printed circuits, in this form common in small form-factor consumer electronics or

for flexible interconnects. Resistant to high temperatures.

-

Pyralux, a polyimide-fluoropolymer composite foil. Copper layer can

delaminate during soldering.

What is PCB Components Sourcing?

PCB Component sourcing refers to the purchasing the PCB components

to be assembled onto the printed circuit board.Component sourcing

can be done in many ways.You can have the suppliers purchase

components from authorized and reliable distributors of their

choice and deliver to you by order.You can also recommend a

distributor where the supplier can source the components from and

deliver to you.Still, you can opt to source for some components and

let another supplier source the rest.Component sourcing can either

be done locally or from abroad. International component sourcing

usually takes around 5-10 working days depending on the duration of

customs clearance.Local sourcing, on the other hand, takes a

shorter time. It is therefore preferred, especially if all the

required components are available because it helps save on time and

production cost.

Specification

| NO. | Items | Capabilities |

| 1 | Layers | 2-68L |

| 2 | Maximum machining size | 600mm*1200mm |

| 3 | Board thickness | 0.2mm-6.5mm |

| 4 | Copper thickness | 0.5oz-28oz |

| 5 | Min trace/space | 2.0mil/2.0mil |

| 6 | Minimum finished aperture | 0. 10mm |

| 7 | Maximum thickness to diameter ratio | 15:1 |

| 8 | Via treatment | Via, blind&buried via, via in pad, Copper in via … |

| 9 | Surface finish/treatment | HASL/HASL lead free, Chemical tin, Chemical Gold, Immersion gold

Inmersion Silver/Gold, Osp, Gold Plating |

| 10 | Base Material | FR408 FR408HR, PCL-370HR;IT180A, Megtron 6(Panasonic);Rogers4350,

Rogers4003, RO3003, Rogers/Taconic/Arlon/Nelco laminate with FR-4

material(including partial Ro4350B hybrid laminating with FR-4) |

| 11 | Solder mask color | Green.Black.Red.Yellow.White.Blue.Purple.Matte Green. Matte Black |

| 12 | Testing Service | AOI, X-Ray, Flying-Probe, Function Test, First Article Tester |

| 13 | Profiling Punching | Routing,V-CUT,Beveling |

| 14 | Bow&twist | ≤0.5% |

| 15 | HDI type | 1+n+1,2+n+2,3+n+3 |

| 16 | Min mechanical aperture | 0.1mm |

| 17 | Min laser aperture | 0.075mm |

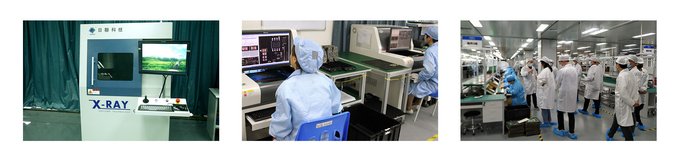

Advantages of XHT

1. 1600 square meters central warehouse

2. Full range of Yageo, Murata, Avx, Kemet RC

3. Temperature and humidity control, first in first out mechanism

4. Solve the problem of R&D samples

5. Professional supply chain team support

6. R&D procurement can also enjoy VIP PCB Assembly service

Prototype PCB Assembly Service Leading manufacturer

Our company established in 2004, has become a trusted name in the

EMS industry, strategically located in Huizhou, Guangdong province,

near the bustling hub of Shenzhen.

With a landscape of 20,000 square meters, our facilities are

equipped to cater to a diverse range of customers across various

sectors, from consumer electronics to medical devices, automotive

components, industrial equipment, power systems, new energy

solutions, and communication devices.

Our comprehensive EMS/ODM/OEM services, including electronic system design, prototype development, PCB

manufacturing, assembly, and rigorous testing, ensure top-notch quality, competitive pricing, and punctual

delivery.

We have a strong electronic component supply chain, we can offer

competitive price for your BOM list.

we've implemented a complete MES (Manufacturing Execution System) covering raw material acceptance, SMT surface mounting, DIP plug-in, and stringent product functional testing.

This system allows real-time monitoring and data tracing of any

abnormal conditions during production, ensuring product integrity

and full process traceability.

Our monthly production capacity of 600 million points ensures

top-notch quality and timely delivery.

Service

We specialize in providing comprehensive EMS solutions to meet the

unique needs of our clients.

Here's a glimpse of the services we offer:

1.Electronic Components Supply.

2.PCB Manufacturing.

3.PCB Assembly.

4.Box Building.

We have a strong electronic component supply chain, we can offer

competitive price for your BOM list.

FAQ

Q: DO YOU TEST ALL YOUR GOODS BEFORE DELIVERY?

XHT: 1. Our products are all original, and we will test the goods before

shipment by professional machines like KEYSIGHT E4991A and KEYSIGHT

E4980.

2. If The buyer need Test Report, we can send the product to

anthoritative institution such as White horse Laboratories(SZ)

Limited,Global Electronics Testing,etc. |

Q: What are the types of solder mask?

XHT: There are traditional epoxy resin IR baking type, UV curing

type, Liquid Photo Imageable Solder Mask and Dry film solder mask.

Currently, the liquid solder mask is the main type. |

Q: How can we guarantee quality?

XHT: Always a pre-production sample before mass production;

Always final Inspection and test report before shipment; |

Q: What is the difference between the HDI board and the general

circuit board?

XHT: Most of HDI use laser to form holes, while general circuit

boards only use mechanical drilling, and HDI boards are

manufactured by the build-up method (Build Up), so more layers will

be added, while general circuit boards are only added once.

|