Fully Automated PCBA Services | Your Premier Manufacturing Partner

In the modern electronics manufacturing industry, fully automated

PCBA services have become the key driver for improving product

quality and efficiency. As a leading electronics manufacturing

service provider, we are committed to offering comprehensive Full

Turnkey PCBA solutions, covering the entire process from design and

procurement to production and testing.

Why Choose Our Automated PCBA Services?

High Precision and Efficiency

Our production lines feature world-class automated equipment,

ensuring the precision of every solder joint from SMT placement to

wave soldering.

Automated inspection systems (AOI and SPI) are integrated at every

critical stage of production, significantly enhancing efficiency

and reducing human errors.

Comprehensive One-Stop Service

We offer end-to-end services, including circuit design, component

procurement, and final product assembly, eliminating the hassle of

dealing with multiple suppliers.

Our automated capabilities easily accommodate the manufacturing of

complex multi-layer PCBs and high-density PCBAs.

Flexible Manufacturing Capability

Whether it’s small-scale prototyping or large-scale production, our

automated equipment ensures quick transitions to meet diverse order

demands.

We provide customized solutions for new energy products (such as

BMS protection boards and MPPT controllers) and smart home devices

(such as smart locks).

Stringent Quality Control

Certified with ISO 9001 and ISO 14001, we adhere to a comprehensive

quality management system.

Our automated testing platforms ensure that every PCBA product

undergoes rigorous testing, including functionality and durability

tests, before leaving the factory.

Applications

Our automated PCBA services are widely applied in:

New Energy Industry (solar inverters, battery management systems)

Industrial Automation (controllers, motor drives)

Consumer Electronics (smart home devices, wearable technology)

Medical Devices (monitors, portable equipment)

Our Advantages

As a professional PCBA manufacturing service provider, we

understand the fast-changing market and high standards of the

industry. We not only deliver efficient and reliable automated

manufacturing services but also work closely with our customers,

supporting them throughout the journey from concept to product

realization

At XHT, we possess the following core technical capabilities. We

continuously expand our competencies, in order to support our

Customers with higher quality levels of printed circuit board

assembly (PCBA), box build, systems integration, and support

services.

- Standards: Production in accordance with international standards,

IPC Class 2 & 3

- SMT: software-controlled, high-speed SMT Assembly lines (01005)

inc. PoP, pin-in-paste, fine-pitch BGA

- THT: automated Through-Hole Assembly - Wave Soldering (Nitrogen) &

Manual Soldering

- Coating: Automated conformal Coating & Potting technologies

- Test: FCT test development and a variety of testing methods,

including. ICT, Safety, Environmental

- Inspection: Inline 3D AOI, inline 3D SPI inspection, 3D X-Ray

- Quality Control: Incoming inspection & in-process measurements

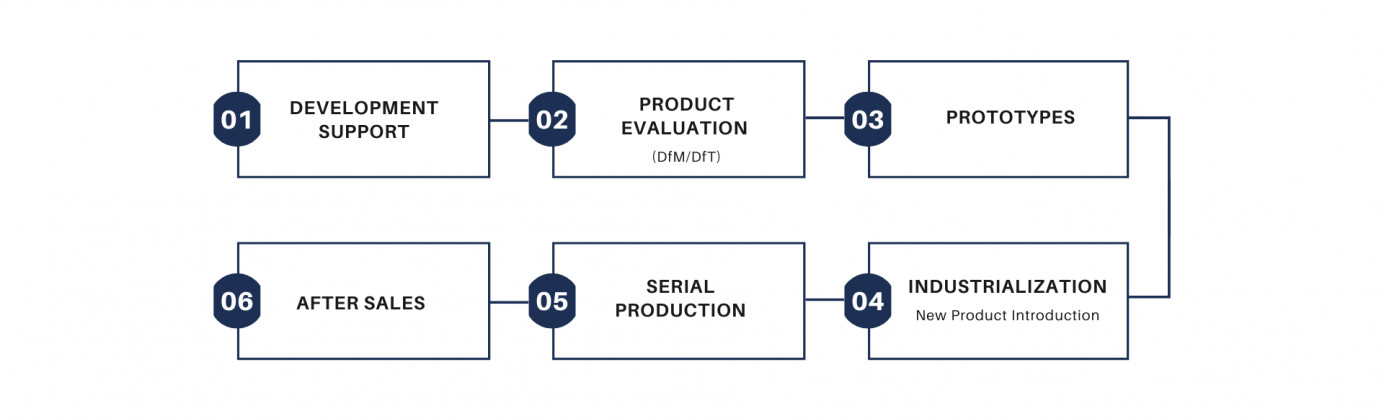

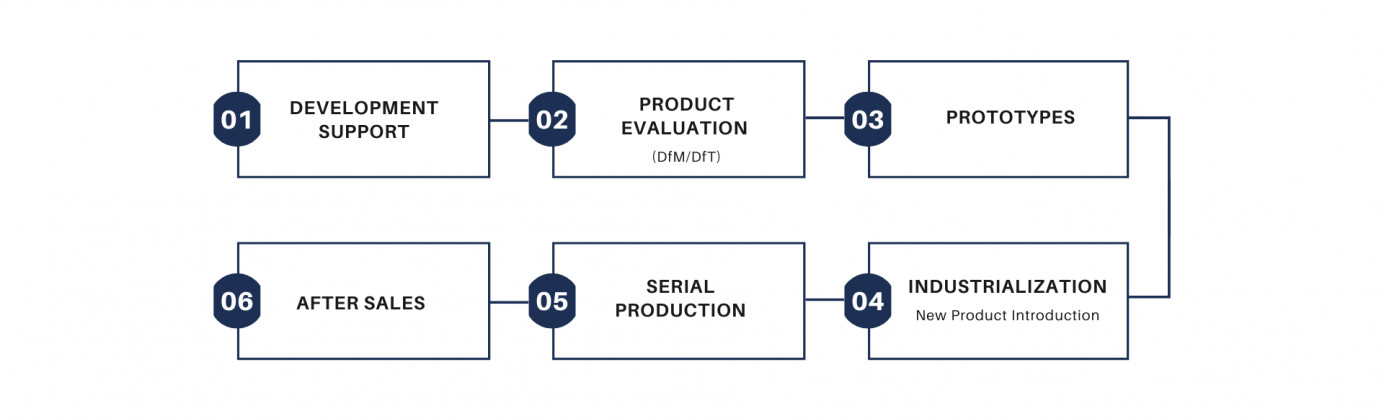

We support our Customers at each stage of the product life cycle

Printed Circuit Board (PCBA) Assembly Highlights

General Capabilities | Surface Mount Technology |

| Pin Thru-Hole |

| Ball Grid Array |

| Functional, Flying Probe, Boundary Scan, and In-Circuit Testing |

| Burn-In |

| Conformal Coating |

| RTV Encapsulation |

| Flexible Circuit |

Equipment | Automated Screen Printing |

| AOI – Automated Optical Inspection |

| Convection Reflow Oven |

| General Products Lead Forming |

| Juki Pick and Place Equipment |

| Wave Soldering (RoHS and Lead) |

| In-Line and Batch Washers |

| Ionic Contamination Tester |

| 3D X-Ray |

| RoHS XRF Analyzer |

| Metcal Solder Stations |

| Agilent 3070 ICT |

| Acculogic Flying Probe |

| Thermotron Environmental Chamber |

| Desiccant Chambers |

| Dispatch Ovens |

| Automated Board Handlers |

| De-Paneling Equipment |

Printed Circuit Board Assembly | Ball Grid Array |

| Clean and No Clean Flux Systems |

| Rigid, Flexible and Rigid / Flexible |

| Single & Double-Sided |

| Placement down to 01005 |

| Package Sizes |

| FBGA |

| LGA |

| QFN |

| Metal Core Insulated |

| Mixed Technology (SMT and Thru Hole) |

| RoHS and Leaded Process |

Assembly Methods | Automated Assembly |

| Hand Insertion |

| Hand Soldering |

| Reflow |

| Wave Solder |

| Additional Services Provided | Conformal Coating |

| Repair & Refurbishment |

| Length | Min 2” |

| Max 18" |

| Width | Min 2” |

| Max 18" |

| Thickness | Min .031” |

| Max .125" |

| Lead Time (Manufacturing) | Standard 2 weeks |

| Production Volume | Low Volume to High Volume Prototype |

Product Packaging:

The EMS PCB Assembly product will be packaged securely in

anti-static bags and placed in a sturdy cardboard box with

protective foam inserts.

Shipping:

We offer worldwide shipping for the EMS PCB Assembly product.

Shipping options include standard, expedited, and express delivery.

Customers can choose their preferred shipping method during the

checkout process.

All shipments will be tracked and customers will receive a tracking

number once the product has been shipped. Shipping fees will be

calculated at checkout based on the destination and selected

shipping method.

FAQ:

Q1: What service do you have?

XHT: We provide turnkey solutions including PCB design, Software

development, PCB Assembly, Enclosure design, Mold-making, Plastic

injection, Finish product assembly, and function testing.

Q2: What are the main products of your PCB/PCBA services?

XHT: Our PCB/PCBA services are mainly for industries including

Industrial control, Home appliances main boards, automotive

electronics, Consumer electronics, Medical equipment, bank

equipment, smart home, etc.

Q3: Is XHT a factory or trade company?

XHT: XHT is a 20-year experienced professional contract

manufacturer to provides a stop Turnkey PCB assembly and

electronics manufacturing service.

Q4: Can we inspect quality during production?

XHT: Yes, we are open and transparent on each production process

with nothing to hide. Customers are welcome to inspect our

production process and check in-house.

Q5: How can we ensure our information should not let the third

party see our design?

XHT: We are willing to sign an NDA effect by customer side local

law and promise to keep customers' data in high confidential level.

Q6: What files are required to get a quotation from you?

XHT: For OEM PCBA projects, please provide the Gerber data/files

and an indication of related technical requirements as well as any

special requirements if you have them; For ODM projects, please

provide a Function List, so our engineering team can work on it.

Q7: What is the standard delivery term?

XHT: Delivery terms of EXW, FCA, FOB, DDU, etc. are all available

based on each quote.

Q8: How long does it take for a PCBA quote?

XHT: Depends on the project's complexity. Normally 1-2 weeks is

enough for our engineers to evaluate.

Q9: Do you have any minimum order quantity (MOQ) requirements?

XHT: No, we do not have MOQ requirements, we can support your

projects starting from prototypes to mass productions.

Tell us your requirements about the FAQ by CLICKING HERE, so that

we can provide a solution to save your budget and meet your needs!